Learning Center & FAQ

Articles and White papers

How to Check Big Brake Kit Wheel Clearance

Which Ferodo Pad Compound is Right for Me?

Are Carbon Ceramic Brake Discs Better than Iron?

Do I Need Brake Ducts on My Track Car?

Can I Run My OEM Brake Pads on the Track?

How to Interpret a Brake Dyno Plot

How to Choose Racing Brake Fluid

Is it Worth Upgrading My Brakes For the Track?

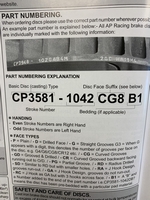

How to Identify AP Racing Brake Components

Track and Racing Brake Pad Owner's Guide

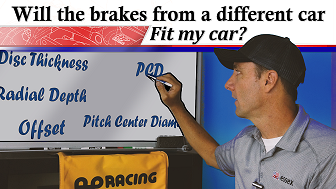

Will the Brake Discs from that Car Fit My Car?

The AP Racing Radi-CAL Story

When Should I Replace My Brake Discs?

Sibling Rivalry: Which AP Racing Radi-CAL is Right for Me, the CP9660 or the CP9668?

Essex Brake Upgrade Guide: Pads, Discs, Lines, Fluid, Big Brake Kit

Brake Fluid Wet or Dry Boiling Point, Which is More Important?

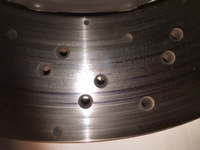

Drilled vs. Slotted vs. Plain Brake Discs and Pad Wear

Big Brake Kit Benefits You May Not Have Considered

Videos

Essex Designed AP Racing Competition Brake Kits: Part 1

Essex Designed AP Racing Competition Brake Kits: Part 2